Vapor Compression Chiller Solutions: Enhancing Cooling Efficiency for Your Business

Vapor Compression Chiller

Efficient cooling is essential for both industrial and commercial operations. Where vapor compression chillers provide a reliable, energy-efficient solution, designed to meet diverse cooling needs. As a trusted vapor compression chiller provider in Bangladesh, we offer high-performance vapor compression chiller systems, customized for your business requirements.

Whether you need the best vapor compression chiller solution or a reliable vapor compression chiller supplier, our solutions ensure consistent cooling performance while optimizing energy usage. With our expertise, we deliver cost-effective, sustainable solutions that improve operational efficiency and reduce overall cooling costs for your facility. Our commitment to quality guarantees lasting reliability and optimal performance.

How Vapor Compression Chillers Work?

Vapor compression chillers operate based on a refrigeration cycle that removes heat from water or air, providing effective cooling for both industrial processes and commercial spaces. The system relies on four key components to maintain efficiency and reliability:

Compressor

The compressor is responsible for increasing the refrigerant’s pressure, causing it to transform into a high-temperature, high-pressure gas. This is the first step in the cycle that enables heat transfer.

Condenser

The high-temperature gas enters the condenser, where it cools down by releasing heat to the surroundings. As it cools, the gas changes into a liquid state, ready for the next phase of the cycle.

Expansion Valve

The expansion valve controls the flow of refrigerant into the evaporator. It reduces the pressure of the liquid refrigerant, causing it to expand and cool down, which enhances its ability to absorb heat.

Evaporator

The refrigerant enters the evaporator and absorbs heat from air or water, lowering the temperature of the space or process. As it evaporates, it returns to the compressor to restart the cycle.

By continuously cycling through these stages, vapor compression chillers offer efficient, reliable cooling, making them an ideal solution for large-scale industrial operations and commercial buildings requiring consistent temperature control.

Get the Best Vapor Compression Chiller Solution for Your Business Today!

Our Vapor Compression Chiller Solutions

As a leading provider of vapor compression chiller solutions, we offer high-performance systems designed to optimize energy efficiency and enhance operational reliability. Tailored for both industrial and commercial applications, our solutions ensure superior cooling performance across diverse sectors.

We specialize in providing customized systems to suit your unique requirements, whether you operate a large-scale manufacturing facility or need precise cooling for a commercial space. Every system is engineered for maximum efficiency, helping you maximize your investment.

Types of Vapor Compression Chiller

Vapor compression chillers are essential components in HVAC systems, utilizing a refrigeration cycle to remove heat from a space. They are primarily categorized based on their cooling methods and compressor types.

Water-Cooled Vapor Compression Chillers

Designed for large-scale operations, water-cooled chillers utilize water as the cooling medium in the condenser. These systems are highly efficient, offering superior heat dissipation, and are ideal for facilities with access to a reliable water supply. Water-cooled chillers are particularly effective in large industrial plants, where high-capacity, continuous cooling is required. These systems typically offer greater energy efficiency compared to air-cooled models, especially in regions with hotter climates.

Air-Cooled Vapor Compression Chillers

Air-cooled chillers use air to cool the condenser, making them ideal for applications where water access is limited or unavailable. These systems are more compact, requiring less space for installation, and are easier to maintain due to fewer moving parts. They are a popular choice for smaller commercial buildings, retail environments, and office spaces. Air-cooled chillers are energy-efficient for medium to low-capacity cooling needs, offering reliable performance while minimizing the need for additional infrastructure.

Centrifugal Vapor Compression Chillers

Centrifugal chillers utilize a centrifugal compressor to compress refrigerant, providing high-capacity cooling. These systems are designed for large-scale industrial and commercial applications, where energy efficiency and cooling performance are paramount. Known for their ability to handle large volumes of refrigerant, centrifugal chillers are ideal for high-demand cooling environments like data centers, hospitals, and large factories. They offer superior energy efficiency, reduce operational costs, and require minimal maintenance compared to other chiller types.

Benefits of Vapor Compression Chillers

Vapor compression chillers provide a reliable, efficient, and cost-effective cooling solution for industrial and commercial applications. They offer several key benefits that ensure optimal performance and lower operational costs:

- Delivers reduced power consumption, minimizing electricity costs.

- Ensures consistent temperature control, crucial for critical operations.

- Energy savings and high efficiency lead to lower overall operational expenses.

- Requires minimal space, making it suitable for various facility sizes.

- Ideal for a wide range of industries, including manufacturing, hospitality, and pharmaceuticals.

- Available in different capacities to meet diverse cooling needs, from small buildings to large-scale industrial operations.

Looking for Energy-Efficient Cooling? Contact Our Vapor Compression Chiller Experts Now!

Applications of Vapor Compression Chillers

Vapor compression chillers are essential for delivering energy-efficient, reliable cooling across various industries. Their versatility and high performance make them a key component in diverse applications. Below are detailed examples of sectors where these chillers plays an important role:

Textile Industry

Maintains optimal temperatures for dyeing, printing, and finishing processes. Vapor compression chillers ensure smooth production by preventing machinery overheating, improving energy efficiency, and ensuring consistent product quality in high-demand environments.

Food Processing Plants

Ensures precise temperature control for food preparation, processing, and storage. Chillers help in preserving flavor, texture, and freshness while meeting food safety regulations, reducing spoilage, and lowering operational costs.

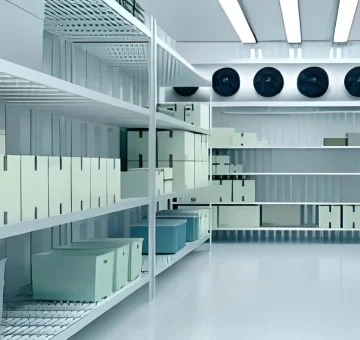

Cold Storage Facilities

Provides consistent cooling to preserve perishable goods such as fruits, vegetables, dairy, seafood, and meat. Vapor compression chillers minimize temperature fluctuations, extending shelf life and ensuring products are stored at the ideal temperature.

Data Centers

Ensures critical cooling for high-density server rooms and electronic equipment to prevent overheating. Vapor compression chillers reduce downtime, enhance energy efficiency, and maintain stable environmental conditions, ensuring uninterrupted operations.

Commercial Complexes

Delivers efficient cooling across offices, retail stores, and shared spaces. These chillers enhance occupant comfort, reduce peak energy loads, and improve energy efficiency in complex multi-zone environments with varying cooling demands.

Healthcare Facilities

Supports cooling for critical areas such as operating theaters, patient wards, and laboratories. Vapor compression chillers ensure consistent temperature control to improve patient comfort, safeguard medical equipment, and maintain sterile environments.

Educational Institutions

Provides reliable cooling for classrooms, lecture halls, and research facilities. Vapor compression chillers improve indoor air quality, enhance comfort for students and staff, and reduce energy consumption through efficient cooling systems.

Manufacturing Plants

Used in process cooling to prevent machinery from overheating during high-intensity operations. Vapor compression chillers help improve productivity, extend machinery life, and optimize energy use, leading to significant cost savings.

Why Choose Us?

As the leading vapor compression chiller supplier in Dhaka, we specialize in delivering tailored cooling solutions that meet the unique needs of various industries. Our chillers are sourced from top global manufacturers, ensuring high-quality performance and energy-efficient cooling. Companies like R-Pac, JCX, and Square Hospital trust us for their critical cooling requirements.

We provide expert support throughout the entire process, from system selection to installation and ongoing maintenance, ensuring smooth operation and reducing downtime. Our high-performance vapor compression chillers are meticulously engineered to minimize energy consumption, cut operational costs, and enhance overall system reliability. These chillers are perfect for demanding environments like hospitals, manufacturing plants, data centers, and commercial complexes, where cooling efficiency and performance are crucial for day-to-day operations.

Optimize Your Cooling Systems with Our Reliable Vapor Compression Chillers. Contact Us Today!

FAQs

Vapor compression chillers provide energy-efficient cooling, lower operational costs, and reliable performance. They are ideal for both industrial and commercial applications, offering a sustainable solution for temperature control.

Yes, industrial vapor compression chillers are designed to handle large-scale cooling needs. They offer high efficiency, reliability, and long-term performance, making them ideal for demanding industrial applications.

By optimizing the cooling process, vapor compression chiller systems consume less energy, reducing both electricity consumption and operational costs.

Yes, commercial vapor compression chillers are perfect for maintaining consistent cooling in hotels, offices, and other commercial spaces. They ensure reliable temperature control while reducing energy consumption.