Vapor Compression Chillers

Chillers that provide efficient cooling by removing heat, ensuring reliable temperature control for a wide range of applications across different industries are called Vapor compression chillers.

Exploring the World of Vapor Compression Chillers

Vapor compression chillers are a common cooling solution, functioning by compressing refrigerant to extract heat from a process or space. The system operates in four main stages: evaporation, compression, condensation, and expansion. This efficient heat transfer ensures reliable temperature regulation, making vapor compression chillers ideal for use in industrial, commercial, and HVAC applications where precise cooling is essential.

What Sets Vapor Compression Chillers Apart?

The unique advantage of vapor compression chillers lies in their highly efficient closed-loop refrigeration cycle. The process begins with the compression of refrigerant into a high-pressure gas, followed by condensation to transform it into a liquid. The refrigerant is then expanded, lowering its pressure, and absorbs heat in the evaporator to cool the environment. This continuous cycle ensures precise temperature regulation, reduced energy consumption, and broad adaptability, distinguishing vapor compression chillers from traditional cooling systems.

Understanding the Mechanics of Vapor Compression Chillers

Vapor compression chillers operate through a four-stage refrigeration cycle: compression, condensation, expansion, and evaporation. First, the refrigerant is compressed into a high-pressure gas and then cooled in the condenser where it becomes a liquid. This liquid refrigerant is expanded, lowering its pressure and temperature, before entering the evaporator. In the evaporator, the refrigerant absorbs heat from the environment or process, effectively cooling it. The cycle then repeats, providing consistent and efficient cooling for various industrial and commercial applications.

Key Benefits of Vapor Compression Chillers

Vapor compression chillers provide energy efficiency, precise temperature control, and versatility across various applications. Their reliable performance and scalable design make them ideal for both small and large cooling needs. Among all of them, some of their key features include,

- Reduces energy consumption and operational costs

- Delivers accurate and consistent temperature regulation

- Suitable for various industrial, commercial, and HVAC applications

- Provides continuous cooling with minimal maintenance requirements

- Adapts seamlessly to both small and large cooling needs

- Supports sustainable practices by minimizing energy waste and emissions

Different Types of Vapor Compression Chillers

Vapor compression chillers come in two main types, each designed to meet specific cooling needs. Understanding these types helps in selecting the optimal solution for various applications.

Air-Cooled Vapor Compression Chillers

Air-cooled vapor compression chillers deliver efficient cooling with a simplified design, making them ideal for installations where water resources are limited. Their key features include:

- High energy efficiency for consistent performance

- Compact design for easy installation in tight spaces

- Minimal maintenance to reduce operational costs

- Reliable temperature control for various applications

- Flexible installation options for different needs

Water-Cooled Vapor Compression Chillers

Water-cooled vapor compression chillers offer superior energy efficiency and high-capacity performance, making them ideal for larger installations. Key features include:

- High part-load efficiency for consistent cooling across capacities

- Excellent energy efficiency, lowering long-term costs

- Greater cooling capacity for larger applications

- Effective heat dissipation through a cooling tower

- Reduced environmental impact with optimized energy use

Top Facilities for Vapor Compression Chiller Applications

Vapor compression chillers are effective cooling solutions suitable for various facilities. They are particularly ideal for industrial settings, commercial buildings, data centers, hospitals, manufacturing plants, food processing plants, cold storage warehouses, and pharmaceutical facilities, where their efficiency and precision ensure optimal temperature control and enhanced operational performance.

Industrial Facilities

Vapor compression chillers are essential in industrial facilities to manage the heat generated by large machinery and processes. They maintain optimal temperatures, preventing equipment malfunctions and ensuring consistent production quality. Choosing vapor compression chillers for industrial applications not only enhances efficiency but also minimizes downtime and extends the lifespan of the equipment.

Commercial Buildings

In commercial buildings, maintaining a comfortable indoor climate is crucial for occupant satisfaction and productivity. Vapor compression chillers effectively regulate temperature and humidity levels, adapting to fluctuating external conditions. Selecting these chillers ensures a tailored cooling solution that meets the specific demands of the space, enhancing both comfort and energy efficiency.

Data Centers

Data centers rely on vapor compression chillers to maintain precise temperature control, which is vital for protecting sensitive electronic equipment from overheating. These chillers ensure optimal operating conditions, thus prolonging the lifespan of servers and minimizing the risk of data loss or downtime. For any data center, investing in vapor compression chillers is essential for operational reliability and efficiency.

Hospitals and Healthcare Facilities

In healthcare environments, vapor compression chillers play a crucial role in maintaining comfortable temperatures for patients and staff while ensuring that critical medical equipment operates within safe temperature ranges. They also help control humidity, reducing the risk of mold and bacterial growth. Choosing these chillers enhances overall safety, comfort, and compliance with health regulations.

Manufacturing Plants

Manufacturing processes often generate significant heat, making efficient cooling necessary for optimal operations. Vapor compression chillers help regulate temperatures, improving production efficiency and product quality. By selecting these chillers, manufacturing plants can ensure a stable environment that supports productivity, reduces waste and enhances overall operational performance.

Food and Beverage Industry

In food and beverage processing, maintaining proper cooling is critical for ensuring product safety and quality. Vapor compression chillers provide consistent temperature control, helping to prevent spoilage and extend the shelf life of perishable goods. Oil free chiller options in these facilities also contribute to maintaining clean and safe environments, essential for compliance with health and safety regulations, ultimately safeguarding consumer health and maintaining product integrity.

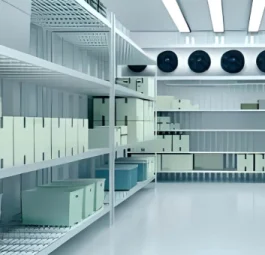

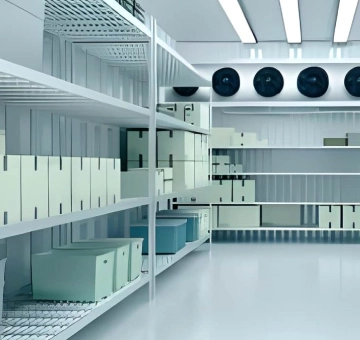

Cold Storage Warehouses

Cold storage facilities depend on effective cooling solutions to preserve perishable goods. Vapor compression chillers help maintain low temperatures, significantly reducing spoilage and waste. Opting for these chillers is vital for cold storage operations looking to maximize product shelf life, improve inventory management, and minimize losses due to temperature fluctuations.

Pharmaceutical Production Facilities

In the pharmaceutical industry, precise temperature control is crucial for ensuring the safety and efficacy of drugs. Vapor compression chillers maintain optimal conditions for storing and processing sensitive materials. By choosing these chillers, pharmaceutical facilities can ensure compliance with stringent industry regulations, enhance product quality, and safeguard public health.

Overcoming Challenges with Vapor Compression Chillers

Vapor compression chillers are vital for efficient cooling in various applications, but they also come with their own set of challenges. Understanding these challenges and implementing effective solutions is essential for maximizing the performance and lifespan of these systems.

High Energy Consumption

Vapor compression chillers can consume significant energy, leading to increased operational costs and environmental impact. To tackle this issue, implementing energy-efficient models and optimizing system controls are vital. Regular maintenance and upgrades to advanced technologies, such as variable speed drives, can also enhance efficiency and reduce energy usage.

Temperature Fluctuations

Inconsistent temperature control can occur due to system malfunctions or improper settings, negatively affecting product quality and operational efficiency. Regular monitoring and calibration of temperature sensors can ensure accurate readings. Investing in advanced control systems can provide real-time adjustments, maintaining stable temperatures and optimal performance.

Refrigerant Leaks

Leaks in refrigerant lines can result in decreased efficiency, increased costs, and environmental concerns. Routine inspections and maintenance are essential for promptly detecting and repairing leaks. Implementing leak detection systems can proactively identify issues before they escalate, ensuring smooth and sustainable operation.

Maintenance Requirements

Regular maintenance is crucial for the optimal performance of vapor compression chillers, but it can be resource-intensive. Establishing a preventive maintenance schedule can minimize downtime and extend the equipment’s lifespan. Training staff on basic maintenance tasks can also reduce reliance on external service providers, ensuring the system remains in peak condition.

Custom Solutions for Vapor Compression Chillers: Partner with Experts

When looking for experts in customized vapor compression chiller solutions, prioritize companies with extensive experience and industry certifications. Reviewing client testimonials and case studies can help assess their expertise and track record. A reliable expert should actively listen to your needs and offer tailored solutions that address your specific requirements.

Tritech is a standout choice, with a proven track record in delivering effective HVAC solutions over the years. Their commitment to quality and customer satisfaction ensures that your vapor compression chiller will meet the unique demands of your facility, providing optimal performance and efficiency.

Get the best vapor compression chiller from Tritech. Let's talk today!

Related Brands

FAQs

A vapor compression chiller is a cooling system that uses refrigerant to absorb heat from a designated area and expel it elsewhere, providing efficient temperature control for various applications.

The chiller operates by circulating a refrigerant through a closed loop system, where it undergoes evaporation and condensation cycles. The refrigerant absorbs heat during evaporation, cooling the surrounding area, and then releases that heat during condensation.

Vapor compression chillers offer several advantages, including high energy efficiency, precise temperature control, versatility for various applications, reliability with minimal maintenance, and scalability to meet different cooling needs.

These chillers are widely used in facilities such as industrial manufacturing plants, commercial buildings, data centers, hospitals, food processing plants, hotels, and cold storage warehouses.

Regular maintenance includes checking refrigerant levels, inspecting and cleaning components, ensuring proper operation of controls, and conducting routine performance assessments to prevent issues and ensure optimal efficiency.

Common challenges include high energy consumption, temperature fluctuations, refrigerant leaks, and maintenance requirements. Addressing these challenges involves implementing effective solutions and regular monitoring.

Contact Our HVAC-R Experts

With experts and sales engineers throughout the country, we're ready to talk, anytime. · How can we help you today?