Water Cooled Screw Chillers

Learn about how water-cooled screw chillers can transform cooling for even the most demanding environments. Built to deliver outstanding performance, they offer unique benefits that upgrade efficiency and reliability like never before.

Introducing Water-Cooled Screw Chillers: Your Solution for Large-Scale Cooling

Water-Cooled Screw Chillers are the ideal choice for large-scale cooling demands. These systems are designed to handle high-capacity cooling precisely, making them perfect for industrial and commercial applications. Vapor compression technology offers consistent performance, enhanced energy efficiency, and reduced operational costs. Whether it’s for manufacturing plants or commercial facilities, these chillers provide reliable, long-lasting cooling solutions tailored to your needs.

How Water Cooled Screw Chillers Work: The Basics

These water-cooled screw chillers operate using a cycle that transfers heat from water to a refrigerant. The process begins with the refrigerant being compressed by screw compressors, which increases its pressure and temperature. The high-pressure refrigerant then moves through a condenser, where water cools it down, turning it into a liquid. Next, the liquid refrigerant passes through an expansion valve, lowering its pressure and temperature. Finally, it enters the evaporator, where it absorbs heat from the water, cooling it. This cycle repeats continuously to deliver efficient, large-scale cooling.

Key Benefits of Water Cooled Screw Chillers

Water-cooled screw chillers offer numerous advantages for large-scale cooling needs. They are designed to deliver efficient, reliable, and quiet performance, making them ideal for industrial, commercial, and data center applications. Here are the key benefits:

- Reduces energy costs with advanced technology.

- Maintains stable temperatures and reliable heat rejection.

- Operates more quietly than other cooling systems.

- Built to last with minimal maintenance required.

- Adapts to a wide range of cooling needs.

Types of Water-Cooled Screw Chillers

Water-cooled screw chillers come in two main types: single-stage, ideal for medium cooling loads, and two-stage, designed for larger-scale applications. Both provide efficient cooling, with the two-stage model offering higher energy savings for demanding environments.

Single-Stage Water-Cooled Screw Chiller

In this type, the refrigerant is compressed in one step, making it simpler in design and ideal for medium-sized facilities. These chillers offer reliable performance with moderate energy efficiency, making them suitable for commercial buildings, hotels, and smaller industrial operations where cooling demands are steady but not extreme.

Two-Stage Water-Cooled Screw Chiller

This chiller utilizes two stages of compression, which boosts energy efficiency and allows for a higher cooling capacity. The dual-stage process helps in managing larger temperature fluctuations and provides superior performance for larger industrial sites, data centers, or manufacturing plants where high cooling loads and energy savings are essential.

Top Facilities That Benefit from Water-Cooled Screw Chillers

Water-cooled screw chillers are ideal for large-scale cooling in diverse environments, ensuring efficient and reliable temperature control in demanding applications. Facilities that would benefit from it are:

Pharmaceutical Manufacturing

In pharmaceutical manufacturing, maintaining strict temperature control is crucial for drug efficacy and safety. Vapor compression water-cooled screw chillers help regulate temperatures during production, storage, and testing, ensuring that active ingredients remain stable and compliant with regulatory standards. These chillers also support the cooling of critical equipment, such as centrifuges and chillers for laboratory spaces.

Textile Industry

Textile factories rely on consistent cooling to manage processes like dyeing and finishing, which are sensitive to temperature fluctuations. Water-cooled screw chillers help maintain optimal conditions, preventing defects and ensuring vibrant colors. They also support air conditioning systems to keep the production floor comfortable for workers, enhancing productivity.

Chemical Processing Plants

In chemical processing, reactions can generate significant heat. Vapor compression water-cooled screw chillers provide reliable cooling for reaction vessels, distillation columns, and other critical equipment, ensuring safe operation and preventing overheating. These chillers are vital for controlling the temperature during exothermic reactions, helping to optimize production efficiency and minimize risks.

Large Greenhouses

Large greenhouses benefit from precise climate control to optimize plant growth and maximize yields. Water-cooled screw chillers help regulate temperatures and humidity levels, creating an ideal environment for various crops. This control enables year-round production and ensures that sensitive plants receive the right conditions for growth, thus enhancing overall agricultural output.

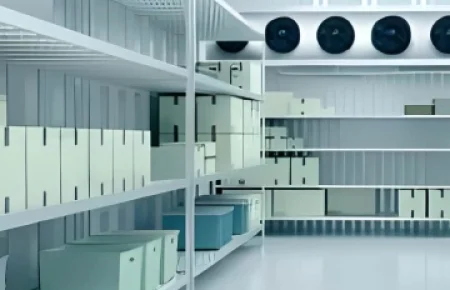

Cold Storage Warehouses

Cold storage warehouses are essential for preserving perishable goods such as food and pharmaceuticals. Vapor compression water-cooled screw chillers maintain the necessary low temperatures, preventing spoilage and extending shelf life. These chillers also help manage humidity levels, ensuring that products remain fresh and safe for consumption.

Hospital Surgical Suites

Surgical suites in hospitals require strict environmental control to ensure patient safety and comfort. Vapor compression water-cooled screw chillers maintain a stable temperature and humidity level, providing a controlled environment for surgical procedures. This consistency helps reduce the risk of infection and supports the overall well-being of patients during surgery and recovery.

Challenges and Solutions: Keep Your Chiller Running Smoothly

Maintaining a water-cooled screw chiller presents several challenges that can impact performance and efficiency. Understanding these challenges is essential for ensuring that your chiller operates smoothly.

Refrigerant Leaks

Refrigerant leaks can significantly reduce cooling capacity and increase energy consumption. Regular inspections should be conducted to monitor refrigerant levels and check for leaks. Implementing a preventive maintenance schedule with prompt repairs for detected leaks will help maintain efficiency and prolong the chiller’s lifespan.

Scaling and Corrosion

Scaling and corrosion in water systems can impede heat exchange and lead to overheating. Establishing a cleaning regimen focused on descaling and flushing the systems is crucial. Additionally, employing water treatment solutions will help mitigate these issues, ensuring optimal performance and minimizing downtime.

Component Wear and Tear

Wear and tear on components like compressors and pumps can disrupt operations and lead to costly repairs. Engaging skilled technicians for routine inspections allows for early detection of worn parts, enabling timely replacements and maintaining reliable chiller operation.

Temperature Fluctuations

Inconsistent cooling can compromise product quality, especially in sensitive environments. Implementing advanced monitoring systems to track temperature and pressure levels in real-time can provide alerts for deviations. Quick adjustments can then be made to maintain stable cooling conditions, ensuring product integrity.

Partnering with Experts: Choosing the Right Solution

Choosing the right partner for your water-cooled screw chiller needs involves looking for experienced professionals with a proven track record. Ensure they have expertise in providing tailored cooling solutions and a history of successful projects.

Tritech stands out for its expertise in designing and implementing customized water-cooled screw chiller solutions. With extensive experience and a commitment to innovative technology, Tritech delivers solutions that meet your specific cooling requirements and exceed performance expectations.

Looking for a water-cooled screw chiller? Tritech can help. Get in touch now!

Related Brands

FAQs

Maintenance should be carried out at least twice a year. Regular inspections help identify potential issues early, ensuring the chiller operates efficiently and preventing unexpected breakdowns.

Routine maintenance involves checking refrigerant levels, cleaning components, inspecting water systems for leaks or scaling, and ensuring all mechanical and electrical parts are functioning properly for optimal performance.

Professional service ensures that complex issues are accurately diagnosed and repaired. Skilled technicians optimize performance, address specific problems, and prevent small issues from becoming major, costly repairs.

Prevent costly repairs by scheduling regular maintenance and promptly addressing any signs of malfunction. Early detection and maintenance help avoid major issues and extend the lifespan of your chiller.

Signs that your chiller needs service include unusual noises, inconsistent cooling, frequent cycling, and visible leaks. If you notice these symptoms, arranging a professional check-up is essential.

Yes, Tritech provides expert maintenance and repair services for water-cooled screw chillers. Our team ensures your system runs smoothly, addressing issues promptly and extending the chiller’s operational life.

Contact Our HVAC-R Experts

With experts and sales engineers throughout the country, we're ready to talk, anytime. · How can we help you today?